|

|

|

|

|

Swing Away Conveyors

Aust-Mech Swing Away Conveyors simplify intake from trucks and assists in ensuring maximum conveyor throughput, convenience and safety. Available with 1.5 or 3.0m wide receival hoppers, the later allowing the truck tailgate to be opened to completely empty the corners. Aust-Mech Swing Away Conveyors feature ‘drop down’ support wheels to facilitate mobility and to allow them to be used for a wide variety of applications. Drive is by electric motor, petrol engine or hydraulic motor. Available in a range of capacities the Aust-Mech Swing Away conveyor and be retro fitted to any Aust-Mech mobile Tubeveyor as well as most conveyors, augers and bucket elevators

DESCRIPTION:

- Simple, safe and fast inload from trucks or outload from silos

- Capacities from 2 to 7 tonnes per minute.

- Hopper lengths of 1.5m, 2m and 3m avoids need to rake out corners of truck at end of load.

- Full ball race castor wheels and turntable provide light, fast operation.

- Low line flexible intake hopper is spring loaded to minimise potential damage from tipping trucks. The inload hopper height is nominally 500mm and can be collapsed (squashed!) to 250mm when required.

- Available with electric, petrol or hydraulic drive.

- The Swing Away turntable is attached to a support frame on the Tubeveyor tail by 2 quick attach fixings. The support frame is automatically kept at a constant height and level over the Tubeveyor inlet hopper regardless of ground level or Tubeveyor angle.

- All belt design provides gentle, fast, self cleaning action.

- Flip down transport wheels provide easy mobility between sites and allows it to be used either while attached to a mobile conveyor or independently e.g. to extract from difficult to access silos, or to feed a bucket elevator

- Australian designed and built.

ADVANTAGES:

- No need to reverse trucks to inload grain. Just drive past the tail of the Tubeveyor or elevator etc and stop in approximately the correct place, then just swing the Swing Away Conveyor behind the truck to unload. This saves many minutes per truck load to greatly increase overall throughput.

- No damage to Tubeveyor hopper from reversing or tipping trucks.

- Simple, rugged and versatile design offers real value for money.

- Unmatched for convenience and versatility.

- Whether filling silos bunkers or sheds the Aust-Mech Swing Away will substantially increase throughput, convenience and safety.

- Equally suitable for use with Aust-Mech or other conveyors or bucket elevators etc. Optional lifting undercarriage available when used to feed non Aust-Mech conveyors.

Aust-Mech’s ‘Swing-Away’ conveyor is also the low cost solution for feeding bucket elevators. The concept is simple… truck drives past the elevator (no drive-over pit required), Swing-Away is swung into position, then truck begins unloading directly into the elevator via the Swing-Away!

- Eliminates the expense of drive over pits

- All-belt design is self-cleaning

- Nil damage to even the most delicate legumes

- Collapsible hopper minimises damage to the unit

- Choice of hopper sizes (1.5m or 3.0m for full tail-gate)

- Capacities from 6 to 600 tonnes per hour

- Electric or hydraulic drive options

- NO REVERSING TRUCKS!!

- Equally suitable for use with Aust-Mech or other conveyors or bucket elevators etc.

Optional lifting undercarriage available when used to feed non Aust-Mech conveyors.

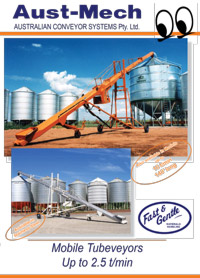

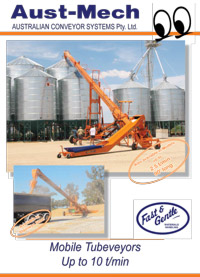

We also suggest you view our Mobile Tubeveyors to 10 tonnes per minute and Mobile Tubeveyors to 2.5 tonnes per minute

BROCHURE